Garching, Germany, May 26, 2015– SUSS MicroTec, a global supplier of equipment and process solutions for the semiconductor industry and related markets, and the Georgia Institute of Technology (Georgia Tech) announced today a collaboration for nanotechnology, bio-medical and semiconductor 3D packaging research.

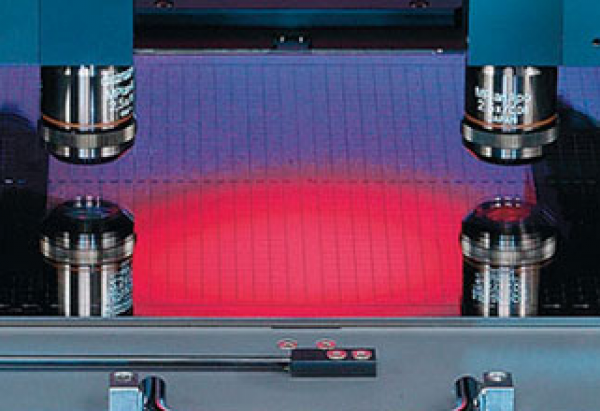

As a part of a broadening alliance, a SUSS mask aligner will be added to a cluster of Suss equipment currently installed in the Institute for Electronics and Nanotechnology (IEN) cleanrooms at Georgia Tech, dedicated for bio-medical device research and fabrication. In early 2015, SUSS also joined Georgia Tech’s Packaging Research Center (PRC) where advanced exposure tools, including excimer laser ablation systems, are utilized for via drilling on non-photosensitive materials. Initial results of the collaboration on via drilling will be jointly presented by Suss and PRC at IEEE Electronic Components and Technology Conference (ECTC) in San Diego on May 26~29, 2015.

“Georgia Tech’s IEN maintains a leading research facility and is part of the NSF-funded National Nanotechnology Infrastructure Network (NINN) formed by 14 US universities”, states Dr. Oliver Brand, Executive Director of IEN. “The addition of this new technology will provide needed functionality for our bio-medical and micro-fluidic research by enhancing our soft lithography capabilities with a wide number of related nanotechnology applications. IEN is dedicated to providing access to this state-of-the-art facility and technology workshops to outside industrial users. It is also Georgia Tech’s vision to train a local workforce for the growing demand in the nanotechnology industry, particularly in the US Southeast region”.

“Excimer laser ablation provides a simple solution for imaging on non-photo-sensitive materials without the high cost of conventional photolithography where multiple coating, exposure, developing and etching processes are required”, says Professor Rao Tummala, Director of Packaging Research Center at Georgia Tech. “We are fortunate to have access to advanced exposure tools like excimer laser ablation systems to demonstrate smaller features such as via drilling down to 1um “.

“Many engineers and researchers get to know SUSS MicroTec through their first experiences with our machines at undergraduate or graduate schools”, says Ralph Zoberbier, General Manager Exposure and Laser Processing at SUSS MicroTec. "We are excited to deepen our relationship with the Georgia Institute of Technology, which is a leading industrial research partner for the high potential growth markets of bio-medical and emerging advanced packaging applications, like 3D-IC, 2.5D interposer solutions and panel size packing”.

Media Contact

Christa Ernst - IEN Communications & Developmentchrista.ernst@ien.gatech.edu

Keywords

Latest BME News

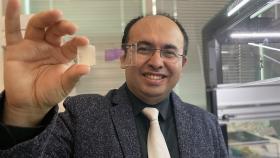

Jo honored for his impact on science and mentorship

The department rises to the top in biomedical engineering programs for undergraduate education.

Commercialization program in Coulter BME announces project teams who will receive support to get their research to market.

Courses in the Wallace H. Coulter Department of Biomedical Engineering are being reformatted to incorporate AI and machine learning so students are prepared for a data-driven biotech sector.

Influenced by her mother's journey in engineering, Sriya Surapaneni hopes to inspire other young women in the field.

Coulter BME Professor Earns Tenure, Eyes Future of Innovation in Health and Medicine

The grant will fund the development of cutting-edge technology that could detect colorectal cancer through a simple breath test

The surgical support device landed Coulter BME its 4th consecutive win for the College of Engineering competition.