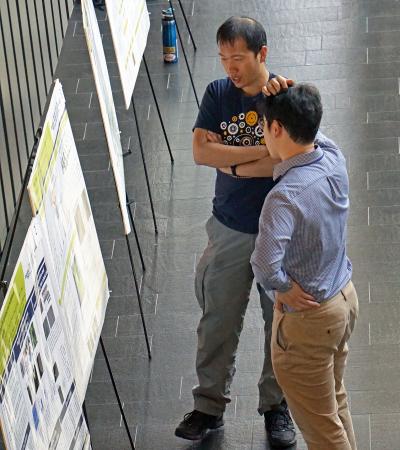

Representatives from the world of cell manufacturing attended a workshop on the role of standards in cell and tissue manufacturing, Oct. 2 at the Georgia Institute of Technology, and event that organizers see as another critical step on the road to developing new technologies and therapies.

The workshop, which provided a forum for sharing some of the latest developments in cell manufacturing from researchers, clinicians, industry, and regulatory bodies, was hosted and sponsored by the NSF Center for Cell Manufacturing Technologies (CMaT), the Petit Institute for Bioengineering and Bioscience, and the Wallace H. Coulter Department of Biomedical Engineering at Georgia Tech and Emory, in conjunction with ASTM International (formerly known as American Society for Testing and Materials), a 120-year-old standards organization that develops and provides technical standards in a wide range of processes, materials, products, and services.

ATSM’s Committee E55 on the Manufacture of Pharmaceutical and Biopharmaceutical Products and CMaT organized the workshop, which took place in the Krone Engineered Biosystems Building at Georgia Tech. Then E55 stuck around for a series of open technical meetings the next two days, Oct. 3-4.

“Our main goal was to demonstrate to members of ATSM International the need for, and crucial role of, standards as we move forward with the translation and commercialization of cell and tissue-based therapeutics,” said Johnna Temenoff, deputy director of CMaT, professor and Associate Chair for Translational Research in the Wallace H. Coulter Department of Biomedical Engineering at Georgia Tech and Emory, and a researcher in the Petit Institute for Bioengineering and Bioscience at Tech.

“Equally important, though, was offering a forum for scientists to discuss how their technologies, and even how they report their data, could promote further understanding of what ‘product quality’ means in this field,” Temenoff added.

Of the 120 or so participants in the workshop, about 25 were members and officers of E55, which has 200 members worldwide, technical experts from the public and private sectors who write voluntary consensus standards designed to drive new innovations in pharmaceutical and biopharmaceutical manufacturing and process control. Members of E55 develop standardized language and definitions of terms, recommended practices, guides, test methods, specifications, and performance standards.

“We feel that we were very successful in getting the right people ‘in the room’ for this workshop,” said Temenoff, who managed the event for Georgia Tech-based CMaT, a National Science Foundation engineering research center that also includes the University of Georgia, University of Puerto Rico at Mayaguez, and the University of Wisconsin-Madison. “During the course of the day we saw important connections being made between ASTM and other standards organizations and industry representatives to determine how E55 in particular can play a key role in developing future standards for cell therapy products.”

From the point of view of the standards makers, the workshop provided some helpful insights.

“At a fundamental level, there is a need for standardization in approaches within different labs, and between different institutions in order to minimize variability through harmonization of materials and methods in order to leverage information and further understanding across the field,” noted E55 officer Duncan Low. “The stated purpose of several groups was to enable reproducible, affordable manufacture of cells. Determining what to measure, how to measure it and how to manufacture with high quality and low cost at large scale were recurring themes.”

Industry representatives were front and center at the workshop, as panel participants and as sponsors (which included IFPAC, RoosterBio, and TerumoBCT). RoosterBio also took part in the industry panel discussion, along with representatives from MilliporeSigma, Celgene, and Immulus.

“Our industry panel, many of whom are partners in CMaT, represented diverse viewpoints, from start-ups to large, multi-national companies,” Temenoff declared. And they hammered home the theme of this workshop.

“Each spoke about the need from their company’s perspective for further standards and best practices in shortening the approval process and streamlining commercialization of cell-based therapies,” Temenoff said. “These are inherently very complex products that require long time-lines and tremendous investment to produce.”

Media Contact

Jerry Grillo

Communications Officer II

Parker H. Petit Institute for

Bioengineering and Bioscience

Keywords

Latest BME News

Jo honored for his impact on science and mentorship

The department rises to the top in biomedical engineering programs for undergraduate education.

Commercialization program in Coulter BME announces project teams who will receive support to get their research to market.

Courses in the Wallace H. Coulter Department of Biomedical Engineering are being reformatted to incorporate AI and machine learning so students are prepared for a data-driven biotech sector.

Influenced by her mother's journey in engineering, Sriya Surapaneni hopes to inspire other young women in the field.

Coulter BME Professor Earns Tenure, Eyes Future of Innovation in Health and Medicine

The grant will fund the development of cutting-edge technology that could detect colorectal cancer through a simple breath test

The surgical support device landed Coulter BME its 4th consecutive win for the College of Engineering competition.